Disruptive Vacuum Gripping NO Pneumatics

Redefining vacuum gripping – lightweight, silent, and energy-free from pneumatics.

Transform Your Ideas Into Reality with Our Proprietary Technology

mateligent is a global leader in smart material systems.

With its subsidiary mateligent nititec GmbH, the group expands its expertise into high-performance shape memory alloy (SMA) actuator technologies.

nititec is at the forefront of developing and industrializing SMA-based system solutions.

Its first spin-off, nititec vacuum gripper GmbH, is bringing a truly disruptive vacuum gripping technology to the market – fully electric, without pneumatics or pumps.

Patents

Production

Europe

Success

Our expertise includes:

Understanding Conceptualization & Your need

Our expertise includes:

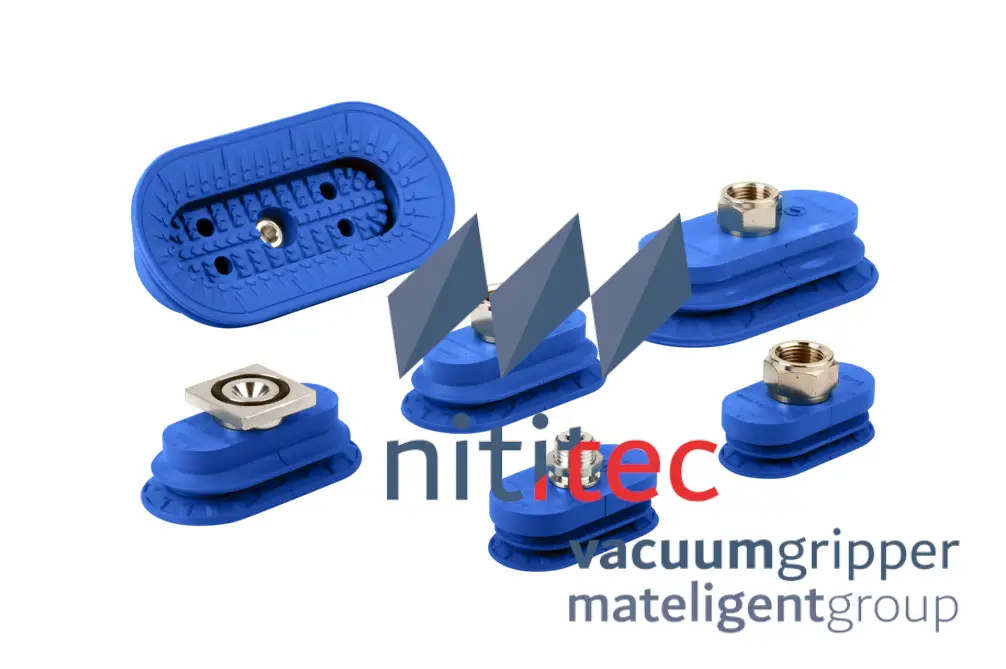

A variety of sizes

Our expertise includes:

What type of control do you need?

Our expertise includes:

Preventive maintenance thanks to integrated sensors

Our expertise includes:

Prototype Design & Assembly

Our expertise includes:

Customized if needed

:

The Future of vacuum gripping

nititec Vacuum Gripper is a disruptive gripping technology that redefines how vacuum is created and applied.

Engineered as a modular toolkit, it enables vacuum-based handling for all non-porous materials – whether steel, glass, plastic, or aluminum; whether large, small, light, or heavy.

Without the need for pumps or pneumatics, the system delivers a lightweight, silent, and energy-efficient solution adaptable to a wide range of industrial applications. Designed for versatility, the nititec Vacuum Gripper allows engineers to configure gripping solutions precisely to their requirements, making vacuum handling simpler, cleaner, and more efficient than ever before.

Sensor can give you safty: Gripped? Vacuum ready? Is the suction membrane wearing out?

Repeatable silent gripping over millions of cycles.

Only the diaphragm itself needs maintenance. And when does the sensor tell you.

Our drives are leading the way in energy-efficient automation

Bus system, with or without sensors, onboard intelligence, re-gripping with leakage compensation, or simple gripping only

Frequently Asked Questions

Get instant answers to some of the most commonly asked questions about our products, services, and technology.

The vacuum drive itself weighs between 30g and 100g, depending on its function and size

Standard Drive

Optional Add-Ons for Maximum Flexibility:

Vacuum sensor – ensures secure holding and communicates directly with your control system

Bus system of choice – scalable connectivity (currently in development)

Re-grip function – intelligently compensates for micro-leakage to maintain reliable vacuum performance

The drive itself can withstand millions of cycles in a normal production environment.

The suction membranes are replaceable and will wear depending on the application.

We like to put it this way: Less than one year of compressed air.

With a 15-second cycle time using a 100 mm membrane, typical energy costs amount to around €500–1,000 per year. That means a return on investment in less than 12 months.